There is a Production type field on the released product form that drives product behavior in production, for example, if you set it to None you may notice that you cannot create neither Formula nor Bill of materials version for it (the buttons are simply grayed out) which also means that you won’t be able to create production or batch order for it. Currently we have following options available in the drop down:

- None, the product is not manufactured, i.e. it can be used in production as a raw material, but you cannot create BOM or Formula version for it.

- Co-product, the product is manufactured as a part of producing another product and should be setup as a co-product in the formula version. Can be used in Formulas for items with production type either Formula or Planning item.

- By-Product, the product is manufactured as a part of producing another product and should be setup as a by-product in formula version. Can be used in Formulas for items with production type either Formula or Planning item.

- Planning item, the items with this type cannot be RAF in production. These are usually used in disassembly or sorting scenarios. Only Co/By products can be RAF of the batch order for the item with this type.

- Formula, the product is produced using Formula.

- BOM, the product is produced using Bill of materials.

In addition, the main difference between BOM and Formula items is when you manufacture BOM item you are limited to one output (i.e. you can RAF only item for which production order is created) at the same time with Formula you can RAF of the production order Formula item as well as Co/By product (depends on what is setup in the formula version).

In this blog post, I want to focus on the “Planning item” type and walk you through the example that I had on one of the implementation projects.

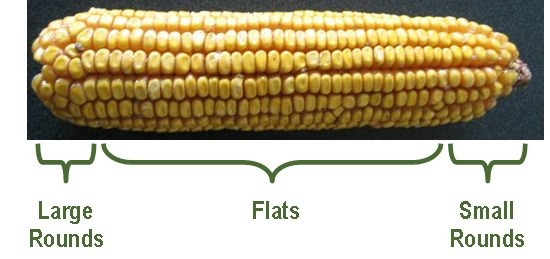

The customer is a manufacturing company that sells maize seeds packed in bags. They buy harvested seed from the grower, shell it, grade it by seed size and in the end, they pack it in bags. Below you can see an example of how the seed size is identified:

Shelling, grading, packing is done through batch orders in MSDyn365FO. Harvested seed is bought with the purchase order. To distinguish between shelled and graded seed in stock we created these as separate item numbers, also we created a separate item number that represents Grading process:

- MAIZE-S Bulk bag of shelled maize seeds, Production type = Formula, UOM = kg, Batch tracked. Formula lines for this item have harvested seed as raw material (MAIZE-H) and the process of shelling is a batch order where we consume harvested seed from stock and RAF bulk bags of shelled seed into stock.

- MAIZE-PL Process of grading shelled seed, Production type = Planning item. Formula lines for this item have shelled seed as raw material (MAIZE-S) and the process of grading is a batch order where we consume shelled seed from stock and RAF bags for different seed sizes separately (MAIZE-G).

- MAIZE-G Graded maize seed (that is product master with LR, F and SR size variants), Production type = Co-product, UOM = kg, Batch tracked, the item is specified as Co-product in the formula for MAIZE-PL.

So the setup in MSDyn365FO as follows:

1. Released products

2. For the MAIZE-G (which is product master), we created Product dimension values that represent different seed size:

3. Then we created released product variants for it:

4. After if is all done we created a Formula for planning item as follows:

5. And added Co-products to it, note that we listed all possible seed size options here with approximate output quantity that can be report as finished of this formula:

6. Once the formula is completed we need to Approve and activate it.

7. After all setup is done we create production order for item MAIZE-PL and Start it.

As I mentioned before the on the picking list we consume item MAIZE-S to issue bulk bag of seeds from stock and on Report as finish step we receive bags of sized seed.

That is all, after the production is complete we need to end the job and end production order to finalize all GL postings.